Calculating Enterprise IoT TCO and ROI: A Comprehensive Guide

In the rapidly evolving landscape of digital transformation, the Internet of Things (IoT) stands out as a technology with immense potential to reshape industries, optimize operations, and create new revenue streams. From smart factories and connected supply chains to intelligent buildings and remote asset monitoring, enterprise IoT deployments promise significant gains in efficiency, productivity, and decision-making. However, realizing these benefits requires substantial investment, and organizations must move beyond the initial excitement to conduct rigorous financial analysis. Understanding the true Total Cost of Ownership (TCO) and projected Return on Investment (ROI) is paramount to building a compelling business case, securing executive buy-in, and ensuring the long-term success and sustainability of any enterprise IoT initiative.

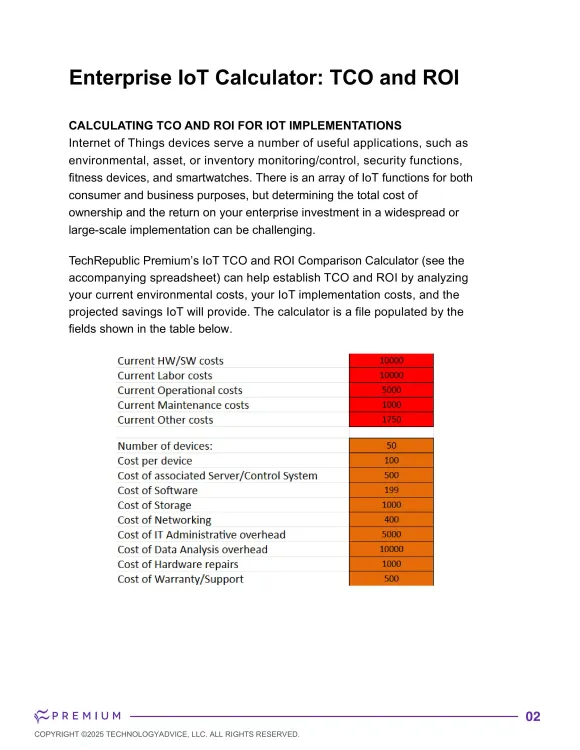

This guide serves as a comprehensive resource for businesses looking to navigate the complexities of evaluating the financial viability of their IoT projects. We will explore the multifaceted nature of IoT costs, the diverse range of potential returns, the challenges inherent in quantifying these factors, and how a structured approach, potentially leveraging tools like an IoT TCO and ROI calculator, can provide clarity and confidence in your investment decisions.

Why TCO and ROI are Crucial for Enterprise IoT

Investing in enterprise IoT is not a trivial undertaking. It involves deploying hardware across potentially vast and distributed environments, developing or integrating complex software platforms, establishing robust connectivity, ensuring stringent security, and managing vast amounts of data. Without a clear understanding of the financial implications, projects can quickly spiral out of control, failing to deliver the expected value.

Total Cost of Ownership (TCO)

TCO goes beyond the initial purchase price of hardware and software. It encompasses the full lifecycle cost of an IoT solution, from planning and deployment through ongoing operations, maintenance, and eventual decommissioning. A thorough TCO analysis reveals the true financial burden over the expected lifespan of the system, helping organizations avoid hidden costs and budget effectively.

Return on Investment (ROI)

ROI measures the profitability of an investment. For IoT, this means quantifying the benefits and savings generated by the deployment relative to its total cost. A positive ROI indicates that the project is expected to generate more value than it costs, justifying the investment. Calculating ROI helps prioritize projects, compare different potential solutions, and demonstrate the value delivered to stakeholders.

Together, TCO and ROI provide a holistic financial picture, enabling informed decision-making and strategic planning for enterprise IoT adoption. Ignoring either metric can lead to inaccurate projections, budget overruns, and ultimately, failed deployments.

Deconstructing Enterprise IoT TCO: Beyond the Sticker Price

Calculating the TCO for an enterprise IoT solution requires a detailed breakdown of all associated costs across the project lifecycle. These costs can be broadly categorized:

1. Initial Planning and Design Costs

- Needs Assessment and Feasibility Studies: Costs associated with identifying use cases, evaluating technical requirements, and assessing potential impact.

- Solution Design and Architecture: Expenses for designing the system architecture, selecting technologies, and planning the deployment.

- Vendor Selection and Procurement: Costs related to evaluating vendors, negotiating contracts, and purchasing initial hardware and software licenses.

2. Hardware Costs

- Sensors and Devices: The cost of the physical endpoints collecting data (e.g., temperature sensors, vibration monitors, cameras, RFID tags).

- Gateways and Edge Devices: Hardware needed to aggregate, process, and transmit data from sensors to the network or cloud.

- Networking Infrastructure: Costs for routers, switches, access points, and potentially new cabling or network upgrades to support IoT traffic.

- Installation and Deployment: Labor and logistical costs for physically installing devices and infrastructure across potentially widespread locations.

3. Software and Platform Costs

- IoT Platform: Licensing or subscription fees for the core platform that manages devices, data ingestion, processing, and analytics.

- Application Development/Integration: Costs for developing custom applications or integrating the IoT platform with existing enterprise systems (ERP, CRM, etc.).

- Data Storage and Management: Expenses for databases, data lakes, and data warehousing solutions to store and manage the potentially massive volume of IoT data.

- Analytics and Visualization Tools: Licensing for software used to analyze data, generate insights, and create dashboards or reports.

4. Connectivity Costs

- Network Subscriptions: Ongoing fees for cellular, satellite, LPWAN (LoRaWAN, NB-IoT), or other network services used to connect devices.

- Data Transfer Costs: Depending on the pricing model, costs associated with the volume of data transmitted.

- Network Management: Costs for monitoring and managing the connectivity infrastructure.

5. Operational Costs

- Maintenance and Support: Ongoing costs for hardware maintenance, software updates, bug fixes, and technical support.

- Monitoring and Management: Labor costs for monitoring system performance, device health, and data flow.

- Energy Consumption: Power costs for devices, gateways, and data centers.

- Software Updates and Upgrades: Costs associated with keeping software current and implementing new features.

6. Security Costs

- Security Software and Tools: Licensing for security platforms, intrusion detection systems, and vulnerability scanning tools.

- Security Monitoring and Management: Labor costs for monitoring security logs, responding to incidents, and managing security policies.

- Regular Audits and Penetration Testing: Expenses for periodic security assessments.

- Firmware Updates and Patching: Labor and system costs for keeping device firmware secure.

7. Personnel and Training Costs

- Internal Staff: Salaries for IT staff, data scientists, engineers, and operational personnel involved in managing and utilizing the IoT system.

- Training: Costs for training employees on using the new technology, interpreting data, and adapting workflows.

8. Data Processing and Analytics Costs

- Cloud Computing Resources: Costs for processing power, storage, and specialized services (e.g., machine learning, AI) on cloud platforms.

- Edge Computing Resources: Costs for processing power and storage on edge devices or local servers.

- Data Scientists and Analysts: Salaries for personnel who analyze the data and derive actionable insights.

Accurately estimating each of these components requires careful planning and collaboration across different departments within the organization (IT, operations, finance, security, etc.).

Unlocking Enterprise IoT ROI: Quantifying the Value

While TCO focuses on the expenses, ROI highlights the benefits and savings generated by the IoT deployment. These returns can be direct and easily quantifiable or indirect and requiring more careful estimation.

1. Operational Efficiency and Cost Savings

- Predictive Maintenance: Reducing unplanned downtime by predicting equipment failures before they occur. This saves costs associated with emergency repairs, lost production, and wasted resources. TechCrunch has covered how predictive maintenance significantly impacts industrial ROI.

- Energy Savings: Optimizing energy consumption in buildings, factories, or fleets based on real-time data and automation.

- Asset Utilization Improvement: Tracking and optimizing the use of valuable assets (vehicles, machinery, tools) to reduce idle time and improve throughput.

- Supply Chain Optimization: Gaining visibility into inventory, logistics, and asset location to reduce waste, improve delivery times, and lower transportation costs. Wired has explored how IoT enhances supply chain efficiency.

- Labor Cost Reduction/Optimization: Automating manual tasks, optimizing workflows, and improving worker productivity through data-driven insights.

- Waste Reduction: Monitoring processes to identify and minimize waste in materials, energy, or production cycles.

2. Improved Productivity and Throughput

- Optimized Processes: Using real-time data to identify bottlenecks and optimize production lines or service delivery processes.

- Faster Decision Making: Providing timely and accurate data to operators and managers for quicker, more informed decisions.

- Enhanced Quality Control: Monitoring production parameters to ensure consistent quality and reduce defects.

3. Enhanced Safety and Compliance

- Worker Safety: Monitoring environmental conditions or worker location to prevent accidents and ensure compliance with safety regulations.

- Environmental Monitoring: Tracking emissions, waste, or resource usage to ensure environmental compliance and reduce penalties.

4. New Revenue Streams and Business Models

- Product-as-a-Service: Offering connected products with value-added services (e.g., performance monitoring, predictive maintenance contracts).

- Data Monetization: Selling or leveraging aggregated, anonymized data insights.

- Improved Customer Experience: Offering new features or better service based on connected products or services.

5. Strategic Benefits

- Competitive Advantage: Gaining an edge over competitors through superior operational efficiency or innovative offerings.

- Increased Agility and Flexibility: Ability to adapt quickly to changing market conditions or operational demands based on real-time data.

- Better Decision Making: Leveraging data analytics for strategic planning and long-term forecasting.

Quantifying these benefits requires establishing clear metrics and baseline measurements before deployment. For example, to calculate the ROI of predictive maintenance, you need to know the historical cost of unplanned downtime before implementing the IoT solution.

Challenges in Calculating Enterprise IoT TCO and ROI

While the principles of TCO and ROI are straightforward, applying them to complex, interconnected IoT systems presents several challenges:

- Complexity and Interdependence: IoT solutions involve multiple layers (devices, connectivity, platform, applications) and often integrate with existing IT and OT systems. Costs and benefits are interdependent and can be difficult to isolate.

- Scalability: Costs and benefits can change significantly as the deployment scales from a pilot project to a full enterprise-wide rollout. Initial costs per device might be high, but operational costs per device could decrease with scale.

- Dynamic Environment: Technology evolves rapidly. Hardware might need upgrades, software platforms release new versions, and connectivity options change, impacting long-term costs.

- Data Volume and Management: The sheer volume of data generated by IoT devices can lead to unexpected costs for storage, processing, and analytics, especially in the cloud. VentureBeat has highlighted the challenges of managing massive IoT data streams.

- Security Threats: The cost of a security breach in an IoT system can be substantial, including remediation, reputational damage, and potential regulatory fines. Estimating this risk is difficult but necessary.

- Quantifying Intangible Benefits: Some significant benefits, like improved safety, better decision-making, or enhanced brand reputation, are harder to assign a precise monetary value to.

- Establishing Baselines: Accurately measuring the impact of IoT requires knowing the performance metrics (e.g., downtime, energy consumption, production yield) *before* the deployment. Establishing reliable baselines can be challenging.

- Long Time Horizons: The full ROI of an IoT investment might not be realized for several years, requiring projections over a longer time horizon, which increases uncertainty.

Addressing these challenges requires a structured approach, realistic assumptions, and continuous monitoring and adjustment of the TCO and ROI models as the project progresses.

Methodologies and Frameworks for IoT Financial Analysis

To overcome the challenges, organizations can adopt structured methodologies for calculating IoT TCO and ROI:

1. Phased Approach

Start with a pilot project in a controlled environment. This allows for testing the technology, validating assumptions about costs and benefits, and refining the TCO/ROI model before a large-scale rollout. The data gathered during the pilot is invaluable for more accurate projections.

2. Activity-Based Costing (ABC)

Apply ABC principles to identify and allocate costs to specific activities within the IoT lifecycle (e.g., device installation activity, data processing activity, maintenance activity). This provides a more granular view of where costs are incurred.

3. Scenario Planning

Develop multiple TCO and ROI scenarios based on different assumptions (e.g., optimistic vs. pessimistic adoption rates, varying data volumes, different maintenance strategies). This helps understand the sensitivity of the financial outcome to key variables and assess risk.

4. Lifecycle Costing

Ensure the analysis covers the entire expected lifespan of the IoT solution, including initial capital expenditures (CapEx) and ongoing operational expenditures (OpEx), as well as potential end-of-life costs (e.g., decommissioning, disposal). TechCrunch has discussed the importance of considering the full lifecycle costs in IoT deployments.

5. Value Stream Mapping

Map the business processes that the IoT solution will impact. Identify how IoT data and capabilities will improve specific steps in the value stream and quantify the resulting benefits (e.g., reduced cycle time, increased yield).

6. Cross-Functional Collaboration

Involve stakeholders from IT, operations, finance, engineering, and business units in the TCO/ROI calculation process. Each department holds crucial information about costs, potential savings, and operational realities.

How an Enterprise IoT TCO and ROI Calculator Can Help

Given the complexity and numerous variables involved, manual calculation of IoT TCO and ROI can be cumbersome and prone to errors. This is where a dedicated calculator tool becomes invaluable.

An effective Enterprise IoT TCO and ROI Calculator typically provides a structured framework to input relevant data and assumptions across various cost and benefit categories. It automates the calculations, allowing users to:

- Systematically Account for Costs: Provides fields to input costs for hardware (devices, gateways), software (platform, applications), connectivity, installation, maintenance, security, personnel, etc.

- Quantify Potential Benefits: Allows users to input estimated savings or gains from areas like reduced downtime, energy efficiency, labor optimization, increased throughput, etc.

- Model Different Scenarios: Enables users to easily adjust variables (e.g., number of devices, data frequency, expected lifespan, discount rate) to see how they impact TCO and ROI.

- Visualize Results: Presents the calculated TCO, ROI, and payback period in clear charts and graphs.

- Identify Key Cost Drivers and Benefit Contributors: Helps pinpoint which factors have the biggest impact on the overall financial outcome.

- Standardize the Analysis: Provides a consistent methodology for evaluating different IoT projects or solutions.

- Build a Data-Driven Business Case: Generates reports and summaries that can be used to justify investment to stakeholders.

A calculator doesn't replace the need for careful data gathering and realistic assumptions, but it significantly streamlines the process and improves the accuracy and consistency of the financial analysis. The resource mentioned in the source HTML, with its seven-page explainer and spreadsheet, likely serves this purpose, guiding users through the necessary steps and providing a template for calculation.

Key Considerations for a Successful IoT Business Case

Beyond the numbers generated by a TCO/ROI calculation, a successful business case for enterprise IoT must also consider:

- Alignment with Business Strategy: How does the IoT project support the organization's overall strategic goals and objectives?

- Stakeholder Buy-in: Have key departments and decision-makers been involved and are they supportive?

- Change Management: How will the organization manage the operational and cultural changes required by the new technology?

- Risk Assessment: What are the potential technical, security, operational, and financial risks, and how will they be mitigated? Wired has extensively covered the security risks inherent in enterprise IoT.

- Scalability Plan: Is there a clear plan for scaling the solution beyond the initial deployment?

- Vendor Ecosystem: Are the chosen vendors reliable and capable of supporting the solution long-term?

- Data Governance and Ethics: How will the vast amounts of data collected be managed, secured, and used ethically and in compliance with regulations?

A strong business case integrates the quantitative financial analysis (TCO/ROI) with these qualitative strategic and operational considerations.

Real-World Examples (Illustrative)

While specific numbers vary greatly by industry and use case, let's consider a couple of illustrative examples of how TCO and ROI play out in enterprise IoT:

Example 1: Predictive Maintenance in Manufacturing

A manufacturing plant invests in sensors on critical machinery to monitor vibration, temperature, and other parameters. Data is sent to an IoT platform for analysis, triggering alerts when anomalies suggest potential failure.

- TCO components: Cost of sensors, gateways, installation, connectivity, IoT platform subscription, data storage, analytics software, training for maintenance staff.

- ROI components: Reduction in unplanned downtime (quantified by lost production value per hour), reduction in emergency repair costs (often higher than planned maintenance), optimized maintenance scheduling (moving from time-based to condition-based maintenance), extended asset lifespan.

- Calculation: The ROI calculation would compare the total cost over, say, five years, against the estimated savings from reduced downtime and maintenance costs over the same period. A successful project might show a payback period of 18-24 months and a significant positive ROI over the full five years. VentureBeat has published articles detailing the ROI seen in Industrial IoT applications like predictive maintenance.

Example 2: Energy Management in Commercial Buildings

A company installs smart sensors and controls in its office buildings to monitor and optimize HVAC, lighting, and other energy-consuming systems based on occupancy, weather, and time of day.

- TCO components: Cost of sensors, smart thermostats, control systems, installation, connectivity, cloud platform for energy management, software licensing, integration with building management systems.

- ROI components: Direct reduction in energy bills (electricity, gas), potential savings on maintenance by optimizing equipment run times, improved occupant comfort and productivity (harder to quantify but a real benefit).

- Calculation: The ROI would compare the total system cost against the projected annual energy cost savings. Payback periods for energy management systems are often relatively short, sometimes within 2-3 years, leading to significant long-term ROI.

These examples highlight that while the specific costs and benefits vary, the fundamental approach to calculating TCO and ROI remains consistent: identify all relevant costs, quantify all achievable benefits, and compare them over a defined time horizon.

Continuous Monitoring and Optimization

Calculating TCO and ROI is not a one-time exercise. After deployment, it is crucial to continuously monitor the performance of the IoT solution against the initial projections. This involves:

- Tracking Actual Costs: Monitor spending on connectivity, cloud resources, maintenance, and personnel to compare against budgeted amounts.

- Measuring Actual Benefits: Collect data on key performance indicators (KPIs) that were expected to improve (e.g., uptime, energy consumption, production yield) and quantify the actual savings or gains.

- Updating the Model: Use the actual performance data to refine the TCO/ROI model and improve the accuracy of future projections or evaluations of other projects.

- Identifying Opportunities for Optimization: Analyze performance data to find areas where the IoT solution can be further optimized to increase benefits or reduce costs.

Continuous monitoring ensures that the IoT investment remains on track to deliver the expected value and allows for adjustments if performance deviates from the plan. It transforms the initial business case from a static document into a dynamic tool for managing the investment.

Conclusion

Enterprise IoT holds transformative potential, but unlocking its true value requires a rigorous financial approach. By meticulously calculating the Total Cost of Ownership and projecting the Return on Investment, organizations can move beyond speculation to build a solid, data-driven business case. This involves understanding the full spectrum of costs, from initial hardware and software to ongoing operations, security, and personnel, and diligently quantifying the diverse range of benefits, from operational efficiencies and cost savings to new revenue opportunities and strategic advantages.

While challenges exist in navigating the complexity and quantifying intangible benefits, adopting structured methodologies and leveraging tools like a dedicated IoT TCO and ROI calculator can significantly streamline the process and improve accuracy. Such tools provide a framework for systematic analysis, scenario planning, and clear visualization of financial outcomes, empowering decision-makers with the insights needed to justify investment and manage expectations.

Ultimately, a successful enterprise IoT deployment is not just about implementing technology; it's about creating measurable business value. A comprehensive TCO and ROI analysis is the essential foundation for demonstrating this value, securing the necessary resources, and ensuring the long-term success of your IoT journey. By committing to this financial discipline, enterprises can confidently invest in IoT, transforming potential into tangible results and gaining a significant competitive edge in the digital age.